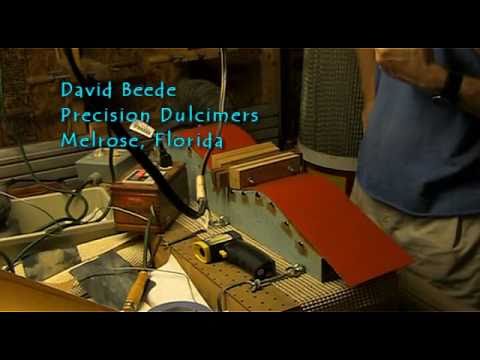

Dulcimer side bending David Beede

musician/member name:

Duration: 00:10:42

description:

Duration: 00:10:42

description:

This is a demonstration of my side bending jig. Unless you're an instrument builder this ten minutes is probably way too much information.I'm using a silicon heat blanket and a form, wrapping the sides in paper first.[A la Bob Taylor.]For more info on my instruments go to my web site. www.davidbeede.com

Here's a pic of one of the early ones. That's a 20 pound chunk of lead in the middle. Works great! The wooden block under the chunk of lead can be thicker or thinner to give wider or narrower waist, it can also be moved left or right to move the waist higher or lower on the instrument.

W'Ok ... guess I'm a victim of reading again. I researched bending the sides a few months ago when I built my first dulcimer. The material I found was on soaking the sides then drying them in a form. I built a 'bath' from 4" PVC. Then I used screws to attach two more pieces of 4" PVC to a piece of marine plywood. The two pieces are in this configuration ...............O ...... O .......... . The sided are clamped at the ends using different thicknesses of wood for how I want the ends of the dulcimer shaped and spaced. I use a movable wooden block in the middle to put the bend closer or farther from the pipe on the 'top' bout end. Vary that block also and it gives your dulcimers waist whatever width you want. I put the sides in the bath, soak 'em in hot water, drape 'em over the PVC and clamp or weight as needed. Then I let them dry. They stay bent. My set up is dirt simple. Should I NOT wet the sides? Is this bad? It's what I found when I started. (The jigs were more elaborate, but mine works and is VERY flexible as far as shaping the sides.) I could do bends for tear drops on it just as easily. Cost? About $10.00 if you buy the stuff. I had enough laying around the basement.

CNC set up yes please

Me 3 David. I'm interested in your set up if you don't mind showing. Thanks.

That was cool, David. I for one would be quite interested in seeing your CNC setup.

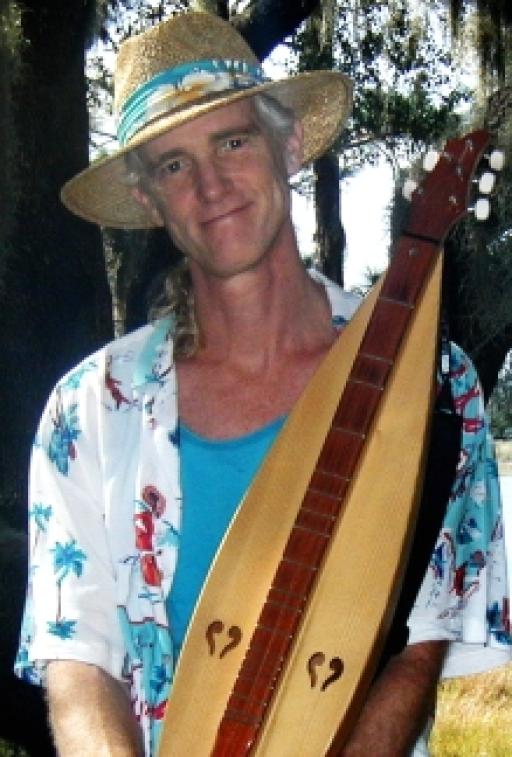

Thanks Dusty - Someday I'll get brave enough to bore the rest of the room with a tour of my CNC machine. It seems odd to some that I use modern high tech tools to build a folksy instrument like a dulcimer. Homer Ledford used to stop during a gig and take out his pocket knife, hold it up and say "I'd like to give you all a tour of my shop." It's fun making dulcimers with a pocket knife... tricky part is paying the bills that way.

You're right, David; since I am not an instrument builder that was more information than I need. But it is fascinating nonetheless. It is amazing how much creativity goes into industrial design for artisans' workshops.

Although I'm not a luthier, I like to see how stuff gets made. Cool video, David.